Vertical Integration

What is Vertical Integration

Definition:

Vertical integration refers to a business strategy where a company expands its operations across different stages of the supply chain, encompassing various levels of production and distribution. This integration involves acquiring or establishing control over businesses that are either upstream (suppliers) or downstream (distributors or retailers) in the production process. Vertical integration aims to enhance efficiency, control costs, and improve overall competitiveness by aligning multiple stages of the production and distribution process under a single corporate entity.

Analogy:

Think of vertical integration as a comprehensive tour operator owning not only the travel agency (downstream) that sells vacation packages but also the airlines and hotels (upstream) that make up the entire supply chain. Similar to how this integration allows the tour operator to have greater control over the entire travel experience, vertical integration in business provides companies with the ability to oversee and optimize various stages of their product or service delivery.

Further Description:

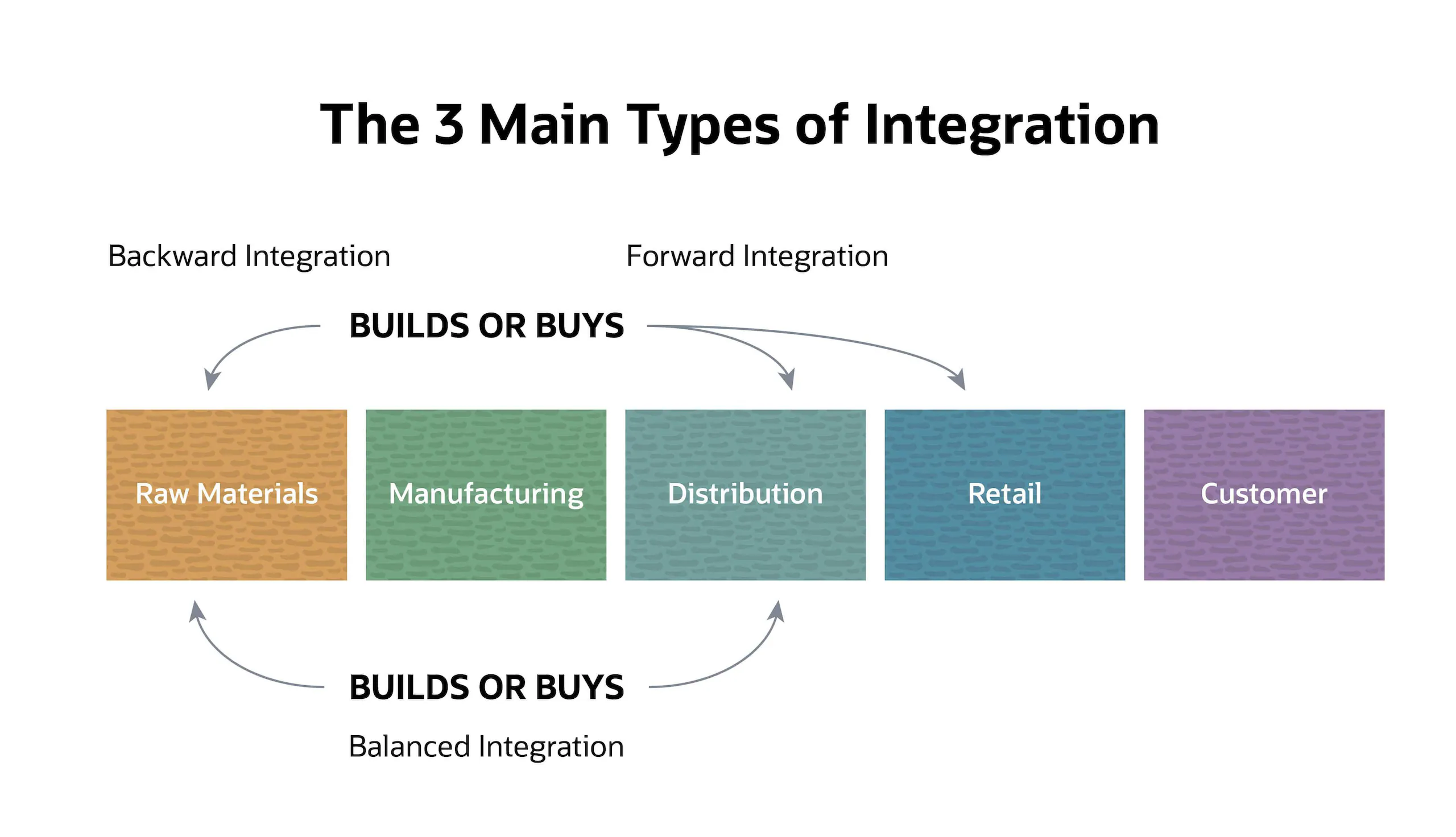

Vertical integration can take two primary forms:

Backward Integration: Backward integration occurs when a company integrates with businesses that supply inputs or raw materials for its production process.

- Example: An automobile manufacturer acquiring a company that produces steel, a crucial raw material for car manufacturing.

Forward Integration: Forward integration involves a company integrating with businesses involved in the distribution and sale of its products or services.

- Example: The same automobile manufacturer acquiring a chain of dealerships to directly sell its cars to consumers.

Why is Vertical Integration Important?

Control Over Supply Chain: Vertical integration provides control over the entire supply chain, reducing dependence on external suppliers or distributors.

Cost Efficiency: By internalizing certain stages of production or distribution, companies can potentially reduce costs associated with third-party transactions.

Quality Control: Direct oversight of production processes allows for better quality control, ensuring that products meet desired standards.

Competitive Advantage: Vertical integration can lead to a competitive advantage by streamlining operations and providing a more cohesive customer experience.

Examples and Usage:

Apple Inc.: Apple practices vertical integration by designing its own hardware, developing software, and controlling its retail stores, creating a seamless and integrated experience for customers.

The Walt Disney Company: Disney’s acquisition of Pixar, Marvel, and Lucasfilm showcases both backward and forward integration, allowing Disney to control content creation, distribution, and merchandising.

Oil Companies: Oil companies often engage in vertical integration by owning both upstream (exploration and production) and downstream (refining and retail) operations to optimize their supply chain.

Key Takeaways:

- Vertical integration involves expanding business operations across different stages of the supply chain.

- Backward integration involves acquiring suppliers, while forward integration involves acquiring distributors or retailers.

- Benefits include supply chain control, cost efficiency, quality control, and a competitive advantage.

- Examples of vertically integrated companies include Apple, Disney, and oil companies.